Setup for Efficient FFB Processing

We specialize in the design and process of know-how of Palm Oil Mills for efficient processing of Fresh Fruit Bunches (FFB). Palm oil fruit offers the highest yield under favorable climatic conditions suitable for its adapted growth and making it essential to adopt best practices for optimal extraction. Fresh fruit bunches are processed instead of stripped fruit, while trying to maintain the quality of palm fruit by all means.

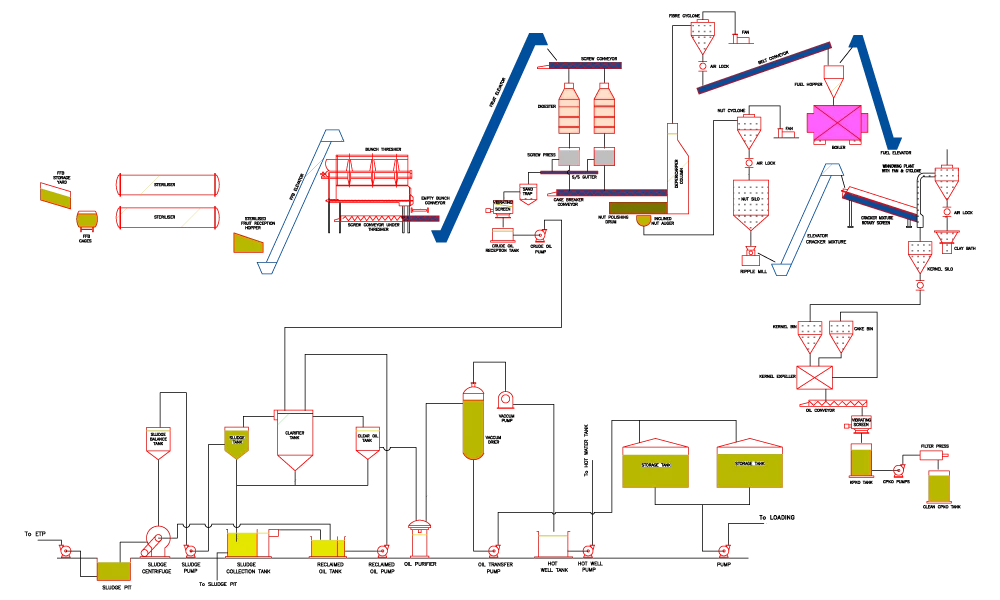

Sterilization

Sterilization is the initial step, crucial for deactivating the lipase enzyme and ensuring efficient mechanical stripping in the succeeding stage. Fresh Fruit Bunches (FFBs). They are then loaded into perforated steel cages with open tops, which are then transported via rails to sterilizers. We use steam to sterilize the FFBs as per the prescribed process cycle.

Stripping

In this phase, the sterilized fruits are separated from the bunch stalks. The stripping operation uses a rotary drum with Tee bars that run parallel to the axis of the cylinder, and spread apart to loosen stripped fruits to fall into a screw conveyor situated beneath, allowing for smooth passage and efficient processing for the next stage.

Digesting and Pressing

Following sterilization and stripping, the fruits enter a digester where it is made soft for oil extraction. The digested palm fruits are then pressed using continuous double screw presses so the oil can be released properly with maximum yield yet retaining quality for subsequent processing.

Clarification and Purification of Oil

The crude oil extracted from twin screw presses does contain impurities such as vegetable matter and sand particles not regarded to be safe for usage. This clarification stage removes such impurities by separating diluted crude oil and collecting it in a settling tank before purification in a centrifuge and drying in a vacuum dryer. Finally, the purified and dried oil is then sent to storage. Sludge water undergoes further processing through decanters to recover entrapped oil and residual solids.

Depericarping and Kernel Recovery Station

After oil extraction, the leftover residue, which is a mix of fiber and nuts, is pressed into cakes and moved along through conveyors. These cakes are then processed further to separate the nuts from the fiber, which allows for a good recovery of the valuable kernels needed for the next stage.

Looking to increase your oil extraction operations? Contact us immediately to discuss your project expressing your concerns and apprehensions. We will solve each one of them. clearing your way. Join the elite engineering group to witness what we speak and let us deliver innovative, high-performance solutions tailored to your needs.