Systems for Multi-Oil Processing

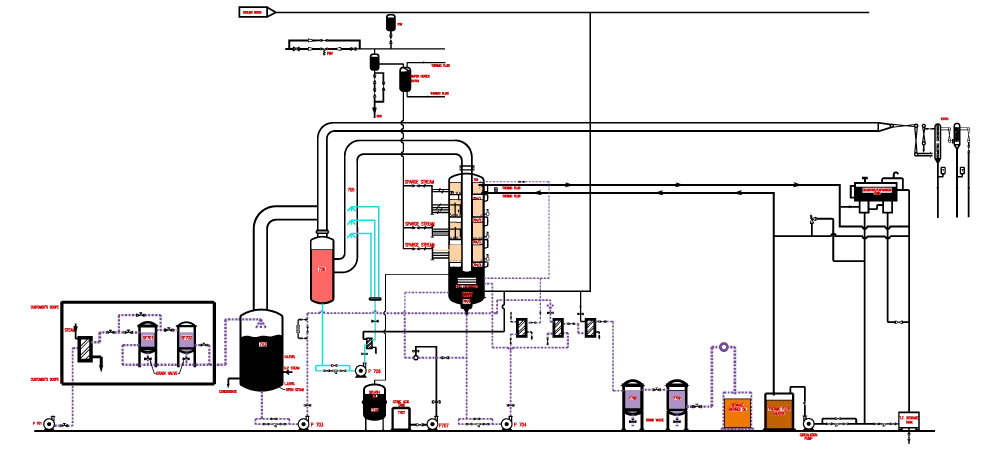

Our vegetable oil refineries and fractionation systems are exclusively designed to carry out and successfully process several oils like sunflower, rice bran, mustard, soya, cottonseed, palm, palm kernel, and corn oil. The refining process includes a series of meticulously designed stages. Our full-fledged process differs based on the type of oil and the designated refining method, decisive of whether chemical or physical.

Vegetable Oil Processes Include:

-

Degumming

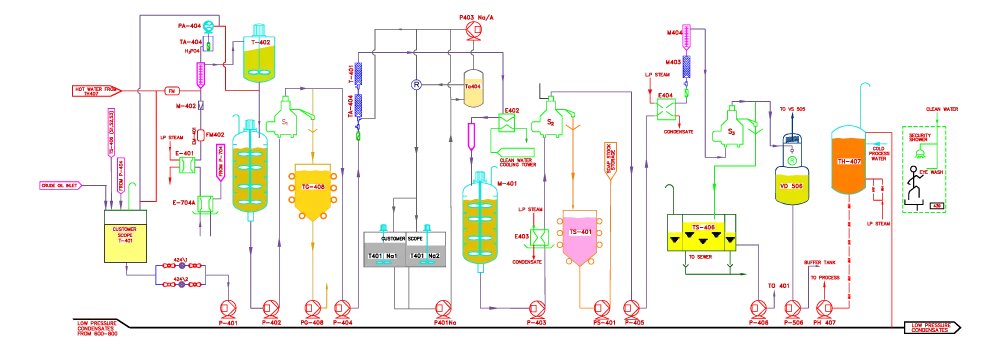

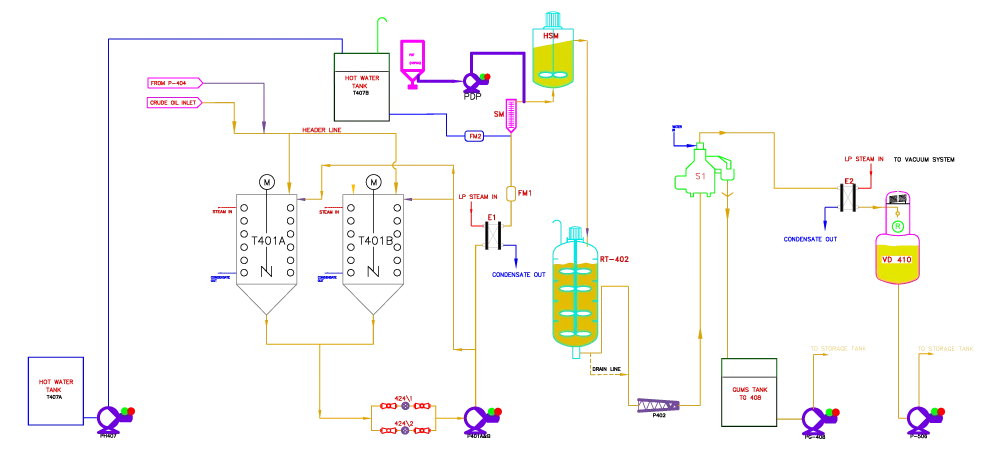

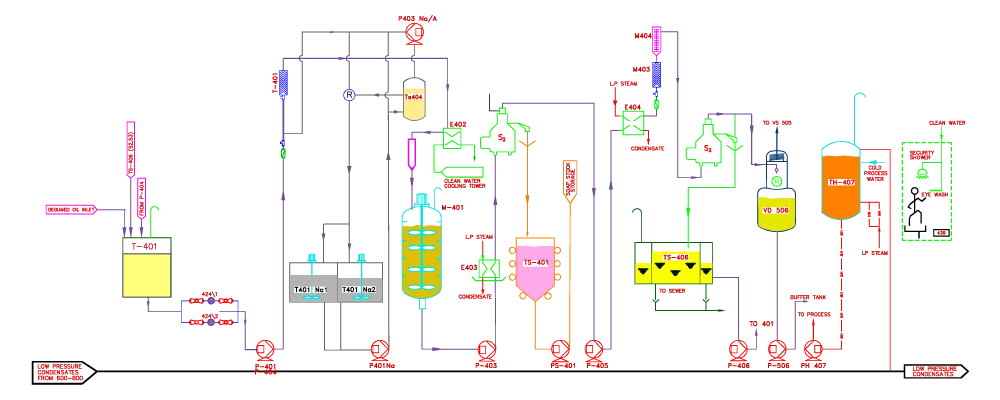

Degumming is the first stage of the refining process, where gums and impurities are removed from crude oil by way of using water or acid treatment. Phospholipids and other unwanted substances are separated to sustain better oil quality. This step enhances efficacy in further refining stages, improving stability and overall purity.

-

Neutralization and Washing

In this stage, free fatty acids are removed from crude oil using an alkali solution, forming soap stock, which is then ideally separated. The oil is methodically washed with water to remove residual impurities. This process ensures improved clarity, stability, and quality for the next refining process.

-

De-waxing

De-waxing eliminates waxes and other crystalline substances from oils like sunflower and rice bran for improved clarity and texture. The oil is cooled to a specific temperature, enabling waxes to crystallize and be removed through filtration. This process safeguards a smooth, high-quality final product with better stability.

-

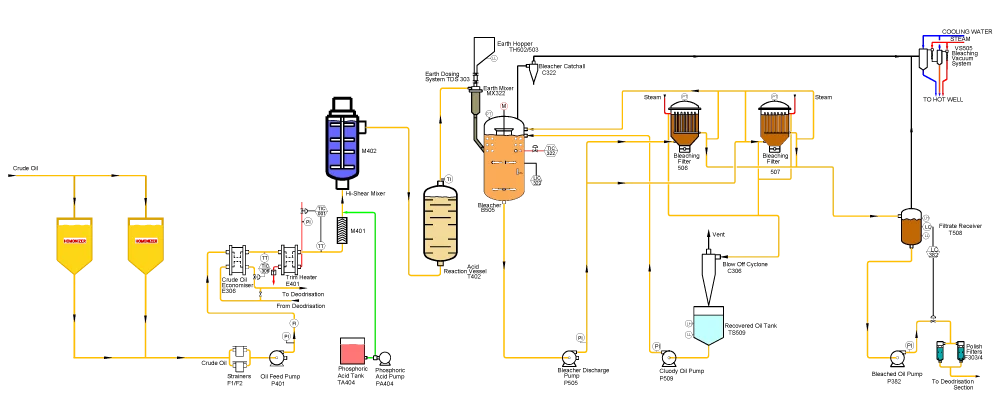

Bleaching

Bleaching removes color pigments, residual gums, and impurities from the oil using activated clay or earth. This process makes the oil clearer, more stable, and produces better quality. By managing temperature and mixing together, impurities are absorbed. Thus, the oil remains clear, pure, and refined.

-

Deodorization

Deodorization eliminates unwanted odors, taste, and volatile compounds from the oil through steam distillation under vacuum. This process nullifies odors and keeps the oil pure and fresh for a better and longer shelf life. By carefully monitoring temperature and pressure, the final product meets high-quality standards for consumption and industrial use.

-

Fractionation

Fractionation involves separating oil into liquid and solid fractions by way of controlled cooling and a filtration process. This stage enhances the quality and utility of oils like palm and palm kernel, producing specialized fractions for various applications. It certifies better texture, stability, and functionality in food and industrial products.

Our practice ensures high-quality, purified oil suitable for various applications.

Looking to increase your oil extraction operations? Contact us immediately to discuss your project expressing your concerns and apprehensions. We will solve each one of them. clearing your way. Join the elite engineering group to witness what we speak and let us deliver innovative, high-performance solutions tailored to your needs.